Ozone nano deodorization, sterilization and purification equipment——Seafood Processing

Ozone Nanobubble Generator for Seafood Processing – Advanced Deodorization & Sterilization Solution

Unlock next-level seafood hygiene, freshness, and flavor with our cutting-edge Ozone Nanobubble Technology.

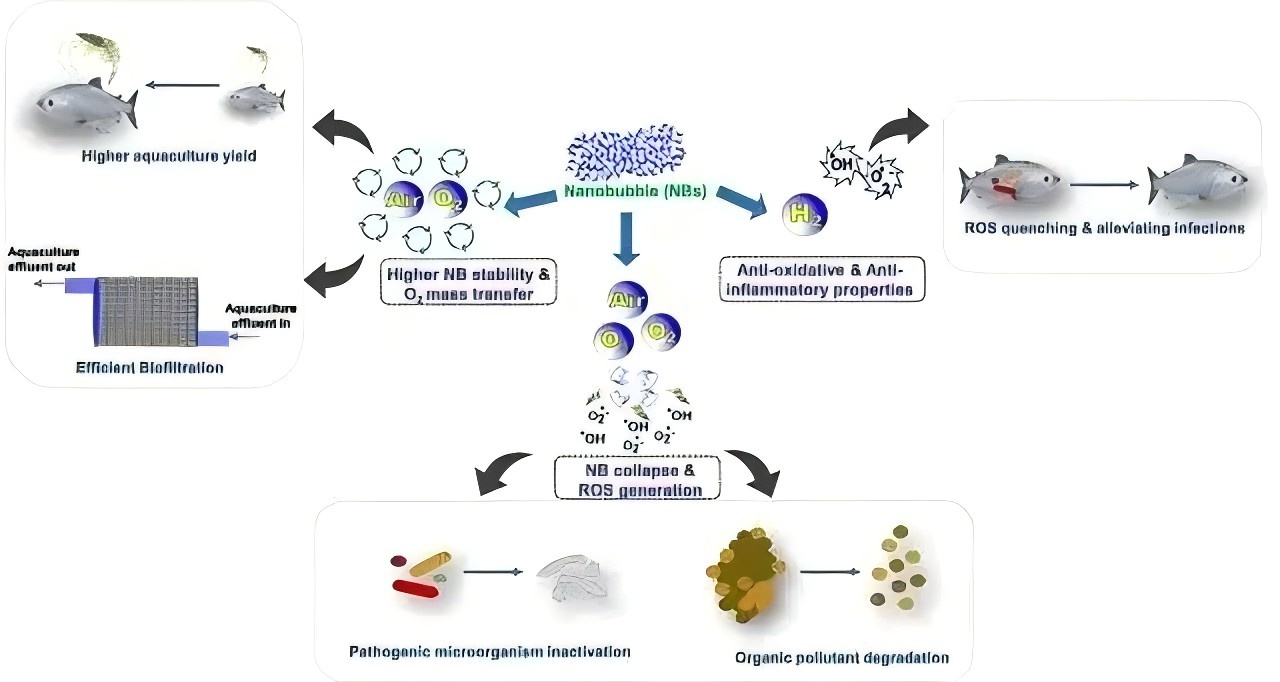

Our Ozone Nanobubble Generator is specifically designed for seafood processing facilities seeking a powerful, chemical-free method to remove fishy odors, reduce microbial contamination, and extend shelf life. By generating ultra-fine ozone nanobubbles, this system penetrates deep into aquatic products—ensuring thorough deodorization, sterilization, and surface cleaning without damaging product texture.

Ozone nanobubble technology offers an advanced solution to one of the seafood industry's biggest challenges: eliminating fishy odors. Our system produces ultra-fine bubbles that reach deep into hidden crevices—such as fish gills and shrimp shells—to thoroughly oxidize and neutralize compounds like tri . This targeted deodorization results in noticeably fresher taste, better mouthfeel, and significantly enhanced product quality.

Ozone nanobubble technology offers an advanced solution to one of the seafood industry's biggest challenges: eliminating fishy odors. Our system produces ultra-fine bubbles that reach deep into hidden crevices—such as fish gills and shrimp shells—to thoroughly oxidize and neutralize compounds like tri . This targeted deodorization results in noticeably fresher taste, better mouthfeel, and significantly enhanced product quality.

Why Micro-Nano Ozone for seafood processing ?